FBT vs. PLC Splitters: Understanding the Difference

Fiber optic networks rely on components like splitters to distribute optical signals effectively. Splitters allow a single input signal to branch out into multiple outputs, a critical function in Passive Optical Networks (PONs), where efficient signal distribution is essential for connecting a single optical line terminal (OLT) to numerous optical network units (ONUs). Among the types of splitters available, Fused Biconical Taper (FBT) and Planar Lightwave Circuit (PLC) splitters are the most common, each offering unique benefits and designed for different applications. This article explores the differences between FBT and PLC splitters, highlighting their structures, uses, and performance characteristics.

FBT Splitters: The Basics

FBT (Fused Biconical Taper) splitters are one of the earliest forms of optical splitters and are known for their simplicity and low cost. In an FBT splitter, fibers are fused and tapered together to create a coupling area, which allows light to split and distribute to multiple outputs.

FBT splitters are produced by fusing two or more optical fibers through heat. Once fused, the fibers are stretched and tapered to achieve the desired split ratio. Since they rely on manual adjustments, FBT splitters are limited in terms of the split ratio they can accurately achieve. Typically, FBT splitters are used for lower split ratios, such as 1:2, 1:4, or 1:8, as higher ratios are less feasible to maintain with accuracy.

In terms of temperature and environmental sensitivity, FBT splitters are more susceptible to changes than other types of splitters. Extreme fluctuations in temperature or humidity can affect the stability of the fused connections, which in turn impacts the consistency of the signal strength. As a result, FBT splitters are commonly used in smaller networks or in installations where environmental conditions are relatively stable.

PLC Splitters: The Modern Solution

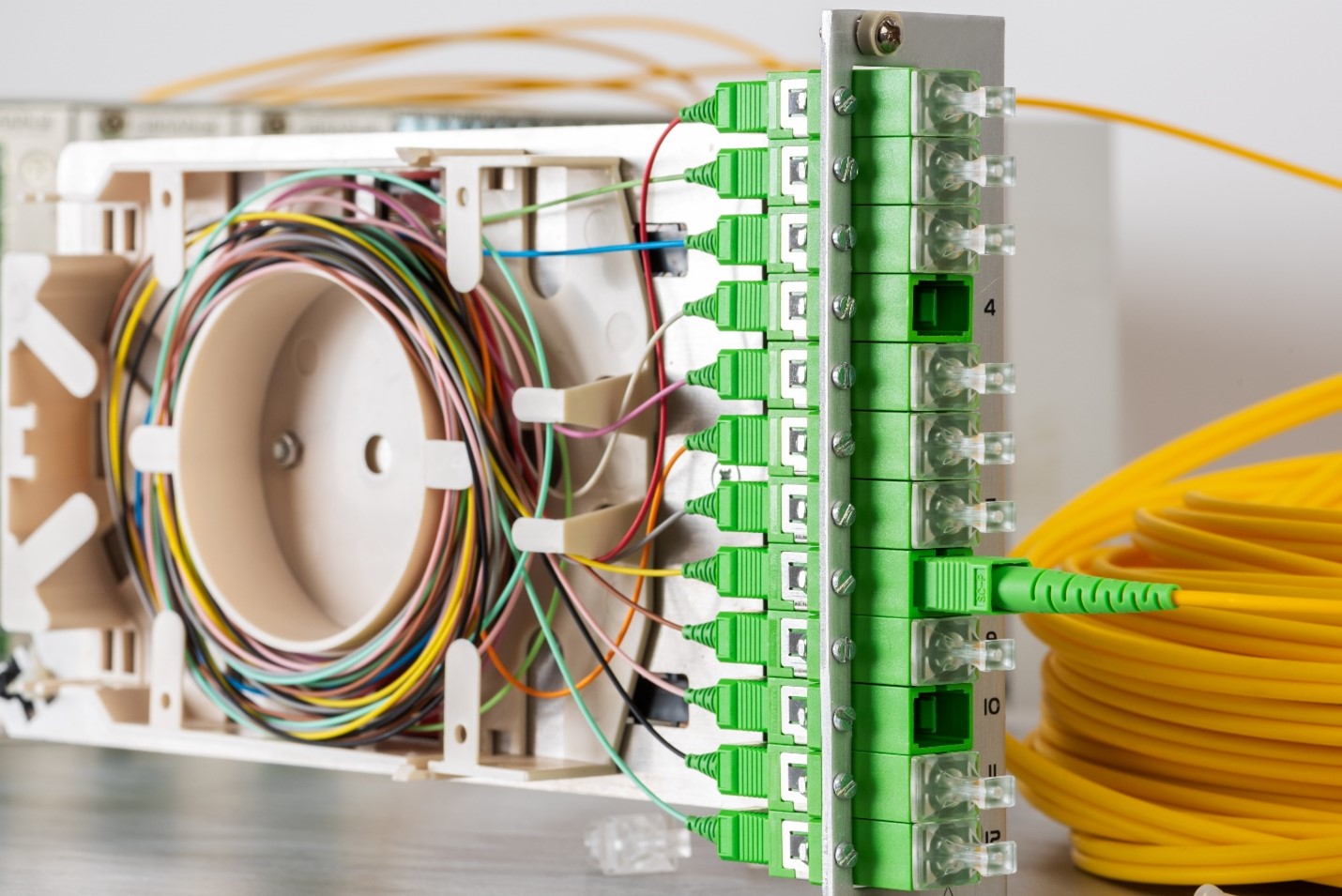

PLC (Planar Lightwave Circuit) splitters are a more recent development, using semiconductor fabrication processes to achieve precise and uniform splitting. These splitters are constructed from silica or glass-based wafers, which allows them to support high-density applications with consistent performance across all outputs. PLC splitters are manufactured using advanced photolithographic techniques that enable exact control over the splitting process. This makes PLC splitters ideal for high split ratios, such as 1:16, 1:32, or even 1:64, where maintaining uniformity across multiple outputs is crucial.

Due to their design and manufacturing method, PLC splitters are highly stable, with strong resistance to environmental conditions. Temperature fluctuations, humidity changes, and other environmental factors have little impact on PLC splitters, making them suitable for large-scale network deployments, including outdoor installations and other challenging environments.

The precision of PLC splitters also ensures equal distribution of signals, which is essential for applications where multiple users or devices rely on consistent signal quality. As a result, PLC splitters are widely used in applications that require high reliability, such as fiber-to-the-home (FTTH) networks, where the optical signal must be evenly distributed to various endpoints within a residential or commercial building.

Structural and Performance Differences

The primary differences between FBT and PLC splitters lie in their manufacturing processes, split ratio capabilities, and environmental resilience. FBT splitters are mechanically simpler and are generally more affordable, as their production requires less precision than PLC splitters. However, this simplicity limits their split ratios and performance consistency. FBT splitters work best for smaller networks that don’t require high split ratios, where environmental conditions are relatively controlled, and where budget constraints are a priority.

PLC splitters, on the other hand, offer the benefits of precision, uniformity, and durability. Their advanced manufacturing process allows for high-density splitting with minimal signal degradation, even at high ratios. Because of these characteristics, PLC splitters are ideal for large networks and high-traffic applications. Their robust structure and resistance to environmental stress make them the preferred choice for networks where performance and stability are paramount, even if they come at a higher initial cost.

Applications of FBT and PLC Splitters

FBT and PLC splitters serve different roles within the telecommunications industry. FBT splitters are often chosen for smaller, less demanding networks, such as Local Area Networks (LANs) or smaller PONs, where they can efficiently distribute signals across fewer endpoints. Their cost-effectiveness makes them suitable for budget-sensitive projects, and they work well in environments with stable temperatures and limited physical stress.

PLC splitters are favored for large-scale deployments, such as FTTH, metropolitan area networks, and other broadband services, where the signal needs to be split across numerous endpoints with high precision. The uniformity and stability of PLC splitters allow network providers to maintain a reliable service, which is especially important for high-demand applications where signal quality directly impacts user experience. Moreover, PLC splitters’ resilience to environmental conditions makes them an optimal choice for outdoor applications or areas where the infrastructure is exposed to varying temperatures and weather conditions.

So, FBT and PLC splitters each bring distinct advantages to the table, shaped by their respective manufacturing processes and structural properties. FBT splitters, with their simpler design and lower cost, are suitable for smaller or budget-focused network applications. PLC splitters, however, excel in high-density, large-scale installations, providing a durable, reliable solution capable of high split ratios with consistent performance across multiple outputs.

So, FBT and PLC splitters each bring distinct advantages to the table, shaped by their respective manufacturing processes and structural properties. FBT splitters, with their simpler design and lower cost, are suitable for smaller or budget-focused network applications. PLC splitters, however, excel in high-density, large-scale installations, providing a durable, reliable solution capable of high split ratios with consistent performance across multiple outputs.

In modern fiber optic networks, the choice between FBT and PLC splitters ultimately depends on the specific requirements of the network, including scale, environmental factors, and budget. Both types have earned their place in the telecom industry, and understanding their unique strengths ensures that each network achieves optimal performance tailored to its needs.