Fiber Optic Cable FRP: Strengthening Performance and Durability

Fiber optic cables are essential for high-speed data transmission in a wide range of applications, from telecommunications to industrial systems. To ensure optimal performance and durability, these cables are often designed with reinforced materials that enhance their mechanical strength and resistance to environmental factors. One such material is Fiber Reinforced Plastic (FRP), which plays a crucial role in many fiber optic cable designs.

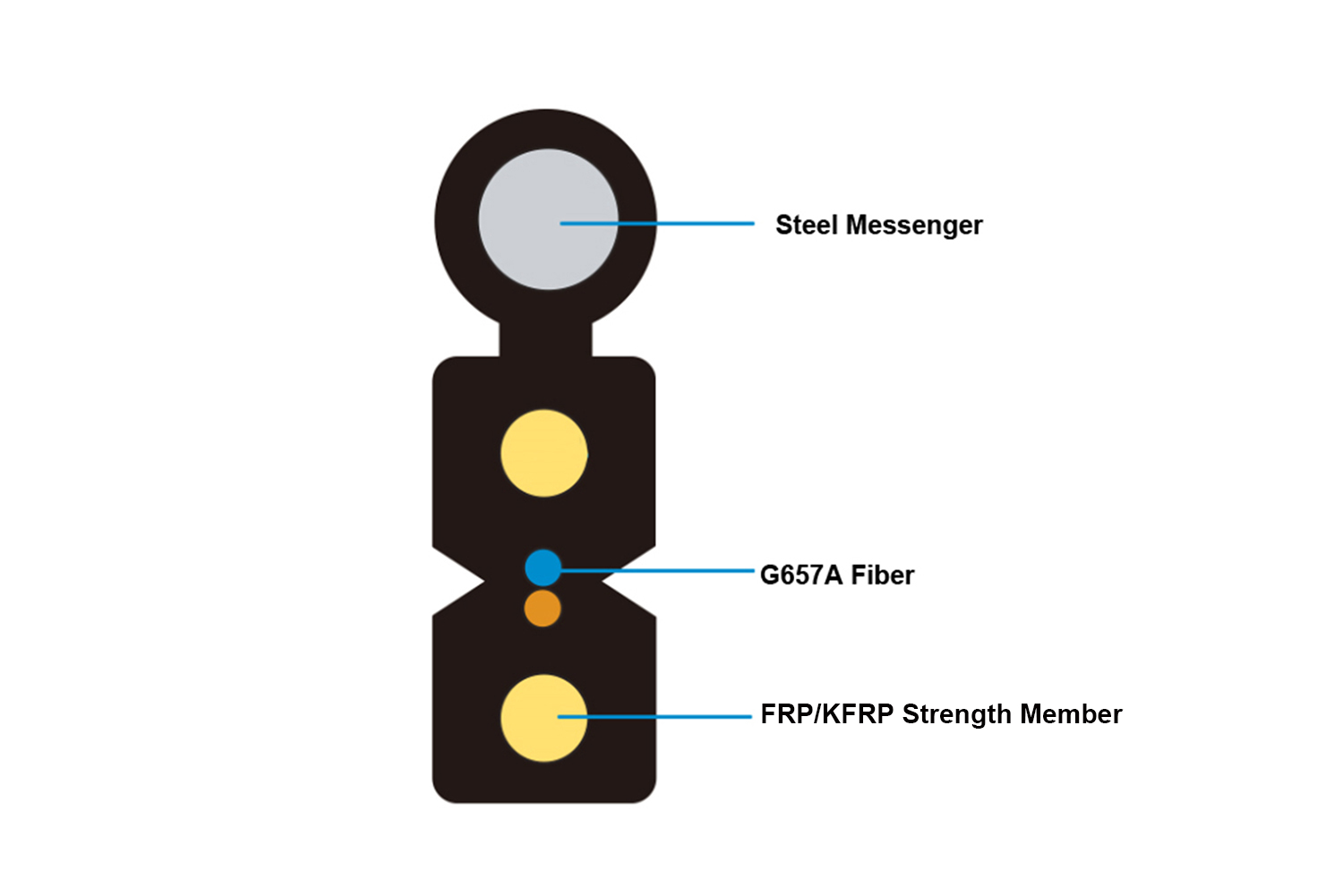

FRP, or Fiber Reinforced Plastic, is a composite material made by embedding fibers (typically glass or carbon) into a plastic matrix, creating a lightweight yet incredibly strong material. In the context of fiber optic cables, FRP is used to strengthen the cable and protect it from external forces, such as pressure, tension, and bending. FRP provides a balance of strength and flexibility that helps maintain the integrity of the fiber optic core while enabling the cable to endure challenging installation conditions and external impacts.

The inclusion of FRP in fiber optic cables significantly enhances their mechanical properties, making them suitable for environments where durability and resistance to physical stress are crucial. For example, FRP is commonly used in outdoor fiber optic cables that are exposed to harsh weather conditions, such as rain, wind, or extreme temperatures. FRP also plays a vital role in underground and aerial fiber optic cables, where additional protection is needed to withstand the weight of the cable or the pressure from surrounding materials.

One of the key features of fiber optic cables with FRP is their ability to resist tensile stress. This means that FRP-reinforced cables can handle significant stretching or pulling forces during installation or as part of their normal operation without causing damage to the delicate fibers inside. The addition of FRP gives the cable more flexibility, allowing it to bend without compromising the performance of the fiber optics.

Another important feature of FRP is its resistance to environmental factors, particularly moisture and chemical exposure. FRP materials are non-corrosive, which makes them ideal for use in areas where fiber optic cables may come into contact with water, chemicals, or other corrosive substances. This resistance helps prolong the lifespan of the cable, ensuring that it continues to function reliably even in challenging environments.

The use of FRP in fiber optic cables also contributes to their overall weight and cost-effectiveness. FRP is lighter than many traditional materials used for cable reinforcement, such as steel, which makes the cables easier to handle, install, and transport. Moreover, FRP is often more affordable compared to other reinforcement materials, providing an economical solution without compromising performance.

In conclusion, Fiber Reinforced Plastic (FRP) is a critical component in modern fiber optic cables, offering a combination of strength, flexibility, and environmental resistance. The addition of FRP allows fiber optic cables to withstand mechanical stress, resist corrosion, and endure tough environmental conditions, making them highly suitable for a wide range of applications in telecommunications, industrial settings, and beyond. By enhancing the durability and longevity of fiber optic networks, FRP ensures that these systems can continue to deliver high-speed, reliable performance over time.